The Hindu : Page 08

Syllabus : GS 2&3 - Governance & Disaster Management

Context :

- The article discusses recurring industrial accidents in India, citing inadequate safety measures, poor inspection rates, and regulatory failures.

- It calls for urgent reforms to strengthen industrial safety governance and ensure accountability.

Industrial and Chemical Disaster:

- It is defined as the release or spill of a toxic chemical that results in an abrupt and serious disruption of the functioning of a society, causing widespread human, material, or environmental losses that exceed the ability of the affected society to cope using only its own resources.

Present Scenario in India

- Recent incidents, such as the Dombivli MIDC chemical factory explosion, highlight the recurring nature of these accidents and their devastating impact on lives and infrastructure.

- Similar incidents were reported in 2016, 2018, 2020, and 2023, raising concerns about persistent risks in the industrial sector.

- India continues to witness frequent fatal industrial accidents, often due to non-compliance with safety regulations, inadequate inspections, and compromised safety practices.

- There is a significant disparity between the number of registered factories and the inspection rates across states like Maharashtra, Gujarat, and Tamil Nadu.

Inadequate Relocation Efforts:

- Despite a decision in 2022 to relocate 156 chemical factories from Dombivli MIDC to Patalganga, no action was taken, exacerbating safety risks.

- The unregistered status of the factory’s boiler further underscored regulatory failures and non-compliance with safety standards.

Way forward

- Enhanced Regulatory Oversight: Strengthening and strictly enforcing safety regulations and standards across all industries. Regular updates to ensure regulations are comprehensive, up-to-date with technological advancements, and aligned with international best practices.

- Improving Inspection and Compliance: Increasing the number of qualified inspectors and improving their training and capabilities.Implementing regular and surprise inspections using modern technologies such as digital monitoring and remote sensing to ensure compliance with safety standards.

- Promoting Safety Culture: Encouraging a proactive safety culture within industries through training, awareness programs, and incentives for compliance.

Key Factors Contributing to Industrial Accidents in India

- Inadequate Regulation and Monitoring: Redundant regulations, including 15 Acts and 19 rules, lack a unified approach for the chemical industry. This fragmentation leads to overlapping jurisdictions and loopholes, weakening oversight and enforcement of safety measures.

- Lack of Comprehensive Chemical Risk Database: The lack of a central database on industrial chemicals and their risks creates a knowledge gap, hindering hazard assessment and safety protocol development.

- Insufficient Worker Training and Awareness: Boiler operation often falls to untrained, contractual workers, lacking proper safety and emergency response training as highlighted by IIT Kanpur.

o This leads to confusion during accidents and increases risks, especially with hazardous chemicals.

- Poor Investment in Worker Safety: Cost-cutting by some industries often neglects safety equipment and infrastructure, such as proper ventilation and fire safety.

o IIT Kanpur study (2023) stresses the need for increased investment in worker safety to reduce industrial accidents.

- Lack of maintenance: The Visakhapatnam gas leak involving benzimidazole raises concerns about maintenance and operations.

o In the Neyveli incident, a boiler being revived unexpectedly blew out, despite not being operational and mainly involving a furnace and steam production.

Major Industrial Disasters in India in the Past:

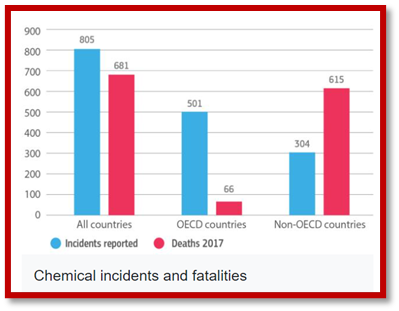

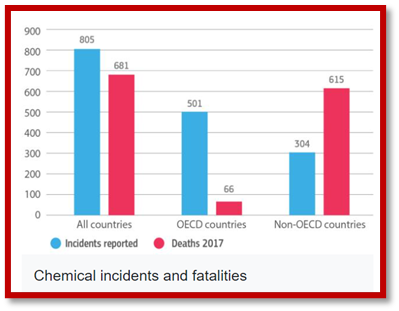

India has a long history of industrial accidents, with over 130 significant chemical mishaps reported recently.

- Bhopal Gas Tragedy (1984): The worst industrial disaster ever, a gas leak from a pesticide plant killed over 3,700 people and injured many more.

- Chasnala Mining Disaster (1975): An explosion in a coal mine caused by methane gas and a subsequent mine collapse led to the deaths of around 700 people.

- Jaipur Oil Depot Fire (2009): A fire at an oil storage facility resulted in 12 deaths and the evacuation of over half a million people. The lack of a proper disaster management plan was a major issue.

- Korba Chimney Collapse (2009): A chimney under construction collapsed due to poor construction practices, killing 45 workers.

- Mayapuri Radiological Incident (2010): Workers unknowingly dismantled a radioactive research irradiator in a scrapyard, exposing themselves and others to radiation.

- Bombay Docks Explosion (1944): A cargo ship carrying explosives exploded in Mumbai harbor, killing around 800 people and causing widespread damage.

Legal Safeguards against Chemical/Industrial Disasters

o Sendai Framework for Disaster Risk Reduction 2015-2030

o UN Convention on the Transboundary Effects of Industrial Accident (1992):

It provides a legal framework for international cooperation on preventing and responding to industrial accidents.

Parties share information, plan emergencies, and help each other during disasters. This reduces risk of widespread accidents.

o Flexible Framework for Accident Prevention and Preparedness (CAPP) (2006) of UNEP: It adopts a flexible approach to help countries, especially developing ones, build programs to prevent and prepare for chemical accidents.

It also offers guidance on creating these programs considering a country's specific needs.

o OECD Programme on Chemical Accidents (1990): It focuses on preventing accidents through information sharing and best practices in chemical safety.

o The Bhopal Gas Leak (Processing of Claims) Act, 1985

o The Environment Protection Act, 1986 (EPA)

o The Public Liability Insurance Act, 1991 (PLIA):

This act mandates insurance for industries handling hazardous substances.This insurance provides financial relief to those affected by accidents involving these substances.

o The National Environment Appellate Authority Act, 1997:

This act establishes the National Environment Appellate Authority (NEAA), which hears appeals regarding restrictions placed on certain industrial activities under the Environment Protection Act, 1986 (EPA), ensuring a fair and transparent process.

o The Hazardous Waste (Management Handling and Transboundary Movement) Rules, 1989:

It requires industries to identify significant accident risks, implement preventive measures, and report any potential hazards to the appropriate authorities.

o Additional Measures:

The National Disaster Management Authority (NDMA) has issued specific guidelines on Chemical Disaster Management. These guidelines provide direction to various authorities for preparing detailed disaster management plans.

Several other laws and regulations, like the Factories Act, 1948, and the Insecticides Act, 1968, also play a role in ensuring industrial safety.